Blog

Investment Castings Supplier

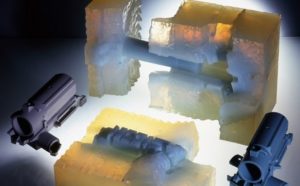

Responsive – Competitive – Quality Driven Investment castings offer many advantages over sand casting and other processes. Our investment casting supplier partner produces close tolerance investment casting for the commercial market. Some of the advantages of using an investment casting over other processes include close tolerances, smooth finish and less machining required. An investment casting […]

It Pays to Buy American

Manufacturing in China costs only about five percent less than in the US, it pays to buy American. Chinese labor costs increased 187 percent in recent years while in the US, labor costs are up just 27 percent for the same period. China’s currency has risen in value by more than 30 percent compared to […]

Reshoring: Manufacturing Comes Home to America

This series has been about how American manufacturers are becoming more competitive in the global marketplace and manufacturing comes home to America. This trend has led to what some people call the “Reshoring of America.” Reshoring is the opposite of offshoring and refers to American companies returning outsourced manufacturing from overseas locations back to the […]

Broader National Issues

Some of the broader national issues making reshoring affordable involve the regulatory and tax environment. We’ll cover these in today’s blog post. Regulatory and Tax Matters While tax rates vary from state to state and each state has their own regulatory supplements to federal legislation, it’s safe to say that our government imposes fewer barriers […]

Strategic Issues Contribute to American Manufacturing Leadership

At CFI, we have initiated a number of strategic initiatives to contribute to American manufacturing leadership to assure your cast components conform to your most stringent specifications. We are ready to work with you in component design to assure you are selecting the most efficient metal and mold design. Here are two of the strategies […]

Return of Manufacturing to Our Shores

Reshoring or onshoring is a process for the return of manufacturing to North America from overseas markets. At one time, it appeared profitable for American OEMs to send some of their production to so-called “low cost manufacturing” markets. The reality of rising costs for labor, transportation, fuel, and electricity – along with such hidden costs […]

Are Rising Shipping Costs Shipping Industrial Jobs Home?

In recent years, rising shipping costs have climbed as much as 71 percent because of higher oil prices, as well as cutbacks in ships and containers, according to IHS Global Insight. The costs for logistics and transportation had the second highest percentage increase during the Great Recession among the production variables examined in a study […]

Is Die Casting Returning to America?

With outsourcing as popular as it’s been for decades, no one would be surprised to learn that the die cast production in the United States is not where it was in 1980. But is the tide finally turning in our favor? Is die casting returning to America? We will explore the onshoring or reshoring movement […]

Advantages and Disadvantages of Casting Pattern Classes Types

The following table summarizes the advantages and disadvantages of the different casting pattern classes types of pattern equipment used by metal casters. Pattern Type Advantages Disadvantages Wood Loose Low cost to produce. Use to produce plastic casting pattern classes. Easily modified. Not suitable for production batches unless converted into plastic before becoming worn. Tend to become […]

Purchasing Pattern Equipment

Balancing Cost & Quality When Purchasing Pattern Equipment The Economics of Good Pattern Equipment Producing superior castings at minimum cost depends in large part on the quality of your pattern equipment. To produce quality results over time, your foundry needs to maintain the pattern equipment to the highest standards. But how do you achieve quality pattern […]

Recent Comments