Investment Casting or Lost Wax

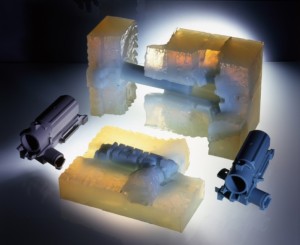

Investment Casting or Lost Wax denotes the mechanical manner of obtaining a mold rather than the material used. It is the process completely investing a three dimensional pattern in all of its dimensions to produce a one-piece destructible mold into which molten metal will be poured.

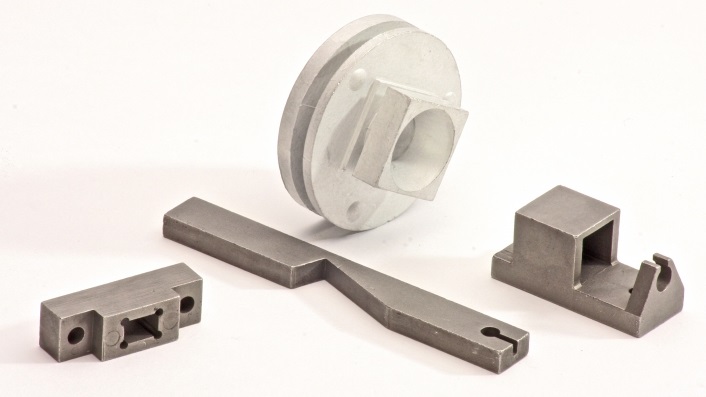

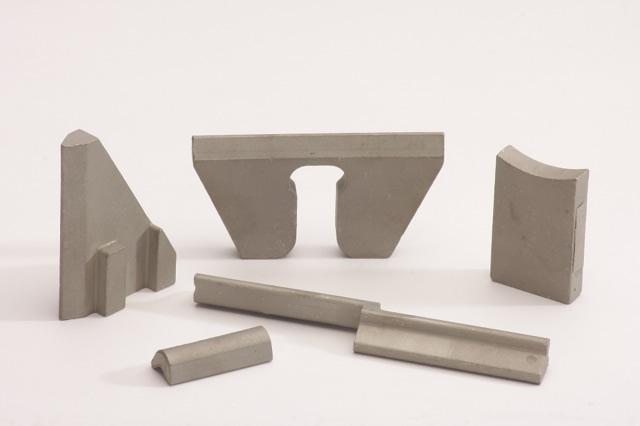

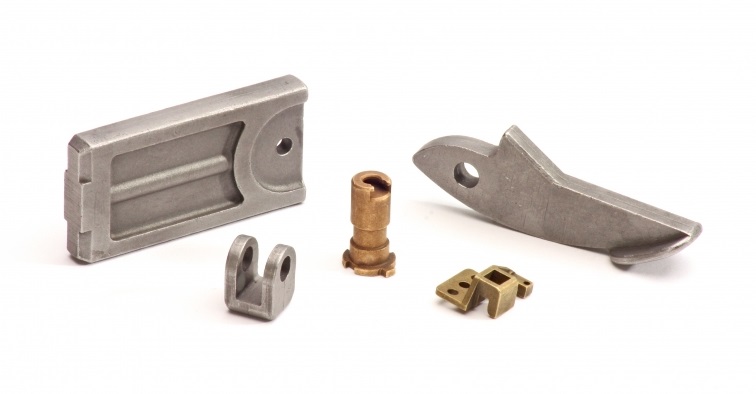

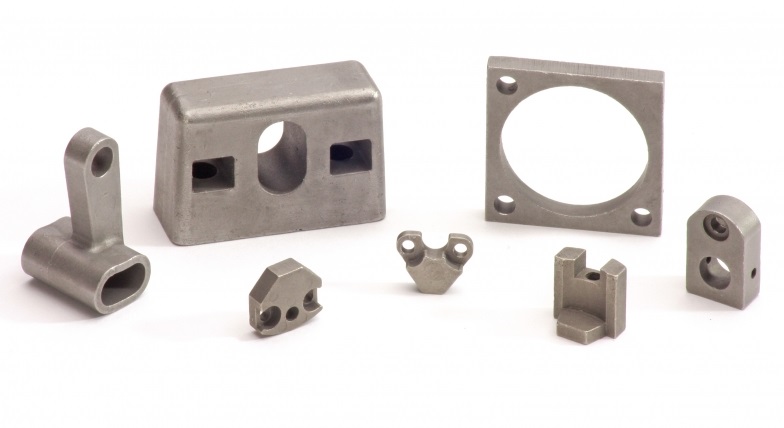

The principle feature of investment casting molding is that a fluid mixture flows around the wax pattern providing excellent detail. This mixture sets with the aid of a hydraulic bond. These wax patterns are assembled on a tree and invested with a ceramic slurry. The tree is then immersed in a fluidized bed of refractory particles to form the first layer of the ceramic shell. The mold is allowed to dry and the process repeated with a coarser material until sufficient thickness has been built up to withstand the impact of hot metal. The wax is then melted out for subsequent recovery and the molds are fired prior to casting. Most materials can be molded by this process but the economics indicate that the shape and complexity of the casting should be such that savings are made by eliminating machining. Unless advantages can be taken of this feature it is unlikely that investment casting will compare favorably with other processes. Accuracy of investment castings is totally dependent on the accuracy of the die and extremely fine tolerances can be achieved with an exceptionally wide range of materials.

Advantages

Extreme accuracy and flexibility of design. Useful for casting alloys that are difficult to machine. Exceptionally fine finish. Suitable for large or small quantities.

Disadvantages

Limitation on size of casting. Casting cost make it important to take full advantage of the process to eliminate some or all machining.

Precision Molding

Investment Casting

| Typical dimensional tolerances, inches | ± .010″, ± .020″ |

| Relative cost in quantity | Highest |

| Relative cost for small number | Medium |

| Permissible weight of casting | Ounces to 100 lbs. |

| Thinnest section castable, inches | 1/16″ |

| Relative surface finish | Very Good |

| Relative ease of casting complex design | Best |

| Relative ease of changing design in production | Fair |

| Range of alloys that can be cast | Unlimited |

Parting Line Influence

When Parting lines are considered, very close tolerances are difficult to obtain. A parting line absorbs fractions of inches per inch. A foundry is doing well to hold a parting line to 0.015 inch. Additional measurement is added to the casting tolerance.